The CNC turned parts production at mbo Osswald

CNC turned parts are essential precision components that play a decisive role in many areas of engineering. They are manufactured on state-of-the-art Computerized Numerical Control (CNC) machines and stand out for their high accuracy, repeatability and flexibility. The production concept is based on digitally controlled manufacturing processes, in which a workpiece is brought into the desired geometry with computer-precise control — producing mechanical components that combine complex shapes, tight tolerances and excellent surface finishes. For demanding technical applications, CNC turned parts are therefore indispensable when consistently high quality, series-production capability or adaptability to new designs are required.

In addition to traditional series production, CNC technology also enables rapid changeovers between different part geometries and batch sizes — from prototype to large-scale production — making short-notice modification requests or special solutions economically feasible. By using the latest manufacturing software and trained specialists, mbo Osswald can purposefully implement a wide range of requirements regarding shape, function and material efficiency.

Applications of CNC turned parts

CNC turned parts are an integral part of modern industrial concepts and are used in a wide range of fields. The options for individual customization, the specific material properties and the impressive manufacturing precision make CNC turned parts an indispensable basic and functional element in numerous systems. Their use pays off wherever not only purely mechanical support is required, but also finely tuned tolerances, geometric special solutions or particularly robust connection solutions are needed. Tailor-made CNC turned parts can be optimally adapted to the specific operational conditions and economic objectives of the respective industry through precise machining. This not only guarantees maximum performance and reliability in everyday use, but also ensures precise interfaces in assemblies and a long service life for the machines.

Mechanical engineering

CNC turned parts are essential for mechanical precision in machines. They ensure that assemblies operate stably and reliably by enabling precise component connections. These parts are capable of accommodating complex geometries and withstanding high loads, making them particularly well-suited to the demands of modern mechanical engineering processes.

Vehicle construction

In vehicle construction, CNC turned parts are indispensable components, especially in chassis and other critical systems. They must be able to withstand extreme dynamic loads with ease, such as those that occur at changing speeds and under varying road conditions. Their ability to ensure durable and secure connections improves vehicle safety and contributes to the longevity of vehicles.

Electrical engineering

CNC turned parts are widely used in the assembly of electronic components. They ensure that printed circuit boards and other components remain stable even under mechanical stress. In complex systems such as control cabinets and data centers, they contribute to structural integrity while also supporting efficient heat dissipation.

Medical technology

Because of their precision and their ability to withstand sterilization processes, CNC turned parts are widely used in medical technology. They are employed in highly specialized devices such as medical imaging systems and surgical instruments, where they ensure precise function and operational reliability.

Renewable energy

In the wind and solar industries, CNC turned parts are crucial for the assembly and connection of system components. These parts must meet the strictest requirements because they are exposed to the elements and are responsible for the structural safety of the installations. Their load-bearing capacity and corrosion resistance are critical to the longevity and operational efficiency of these environmental engineering systems.

Furniture industry

In modular furniture systems, CNC turned parts contribute to the stable connection of components. They are capable of ensuring structural integrity while also offering the flexibility required for adjustments in the configuration of shelving systems and other furniture. These parts also support the aesthetically sophisticated integration into high-quality furniture constructions.

Machining areas and materials in CNC turned parts production

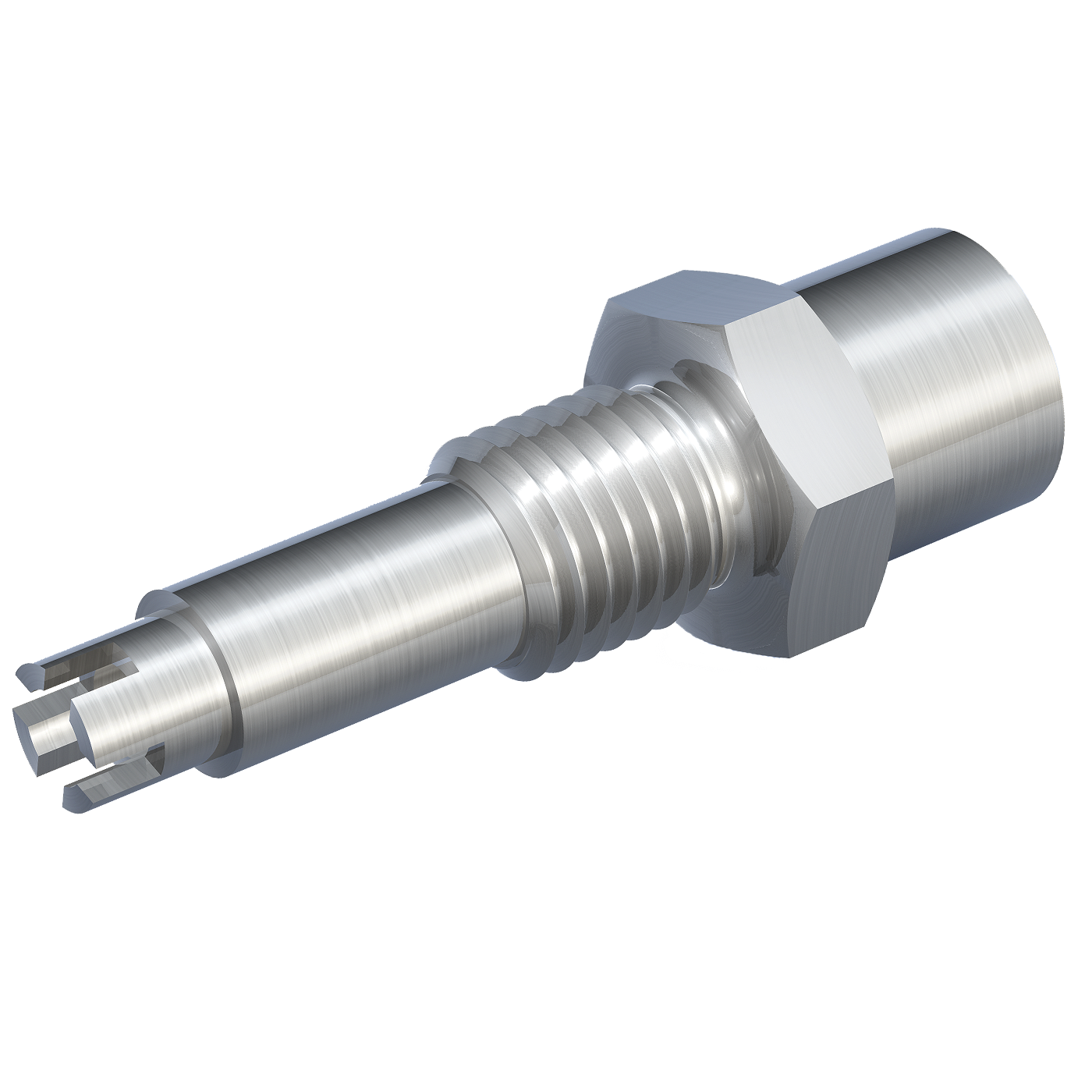

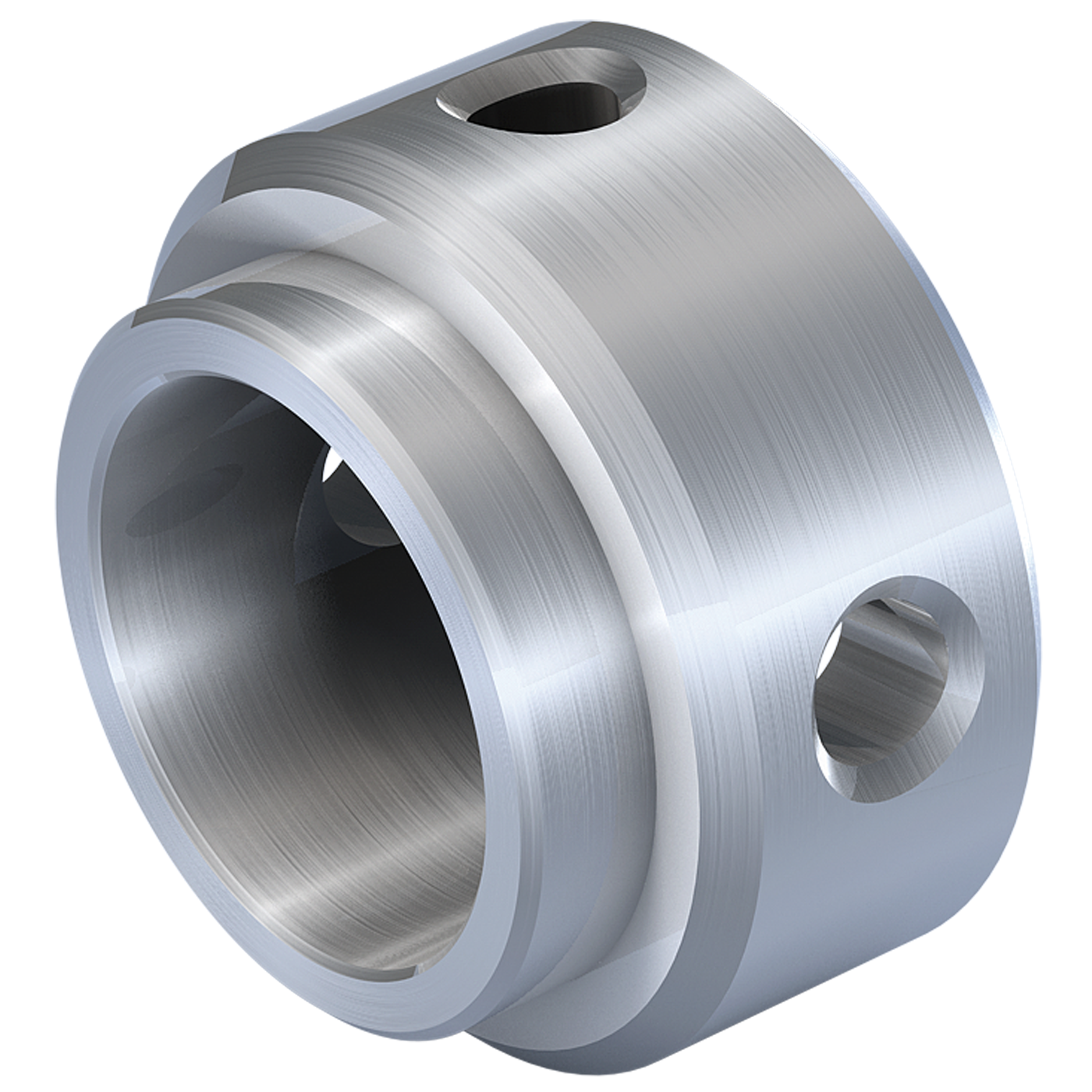

Our CNC turned parts production is characterized by an extremely high degree of technical versatility. We can efficiently and precisely machine round bar stock with diameters from 4 mm to 65 mm and lengths from 5 mm to 350 mm — tailored to your specific requirements. Depending on the application, we produce single parts, small batches, and medium to large series with a consistently high standard of quality and tight dimensional tolerances.

We also offer maximum flexibility in material selection: from conventional undercut steels, through stainless steels in A2 and A4 quality, to special high-strength, seawater- or heat-resistant alloys — providing a wide range of solutions. This ensures that every component is prepared exactly for the particular challenges of your project.

Various shapes and lengths, flexible for any quantity

Thanks to our modern machinery and computer-controlled processes, we produce CNC turned parts in all common geometries and lengths. Whether round, cylindrical, stepped or complex-shaped parts are required: with our flexible production we adapt to your individual needs, from single-part production and small series up to large orders for series production.

Even short-term changes in quantity and product requirements can be implemented without difficulty. Simply give us your specific target — we will ensure an efficient and cost-effective handling.

The most common materials: steels and alloys, flexibly matched

Our CNC turning portfolio includes a wide range of materials for diverse application areas:

- Undercut steel for classic, economical applications

- Stainless steels (A2 quality, A4 quality) for higher corrosion-resistance requirements

- Special steels for particularly high strength, seawater or heat resistance

This ensures that the material basis of your CNC turned part is always optimally matched to the technical environment and level of stress – for long-term safety, reliability and cost-effectiveness.

CNC turned parts – machining and customization

With the help of precise CNC technology, mbo Osswald offers numerous machining options:

These include cross holes, grooves, milling operations, multi‑flat machining, wrench flats, internal hexagons as well as all common metric and inch thread types (regular, fine-pitch, right hand, left hand threads). Very complex shapes, special geometries, custom dimensions and specific markings (e.g. by laser or engraving) can also be implemented precisely. In this way you receive turned parts that meet the highest demands in dimensional accuracy, function and documentation - without any compromise on precision and repeatability.

Various surface finishes for your CNC turned parts

An optimally tailored surface treatment is essential for the function, lifespan and usability of CNC turned parts. We offer a variety of targeted surface treatments — each can be selected to meet your requirements:

Coating

Even from the factory, CNC turned parts can be supplied with electroplated coatings such as zinc plating, phosphating, passivation or bluing. These processes reliably protect your component against corrosion, increase chemical resistance and optimize surface quality – tailored to the operating environment and application.

Treatment

For special applications we offer degreasing or the application of an exactly defined oil film as temporary protection or to facilitate assembly processes. These surface treatments are coordinated with you and carried out precisely according to your specifications.

Mechanical machining

Through precise grinding, CNC-turned parts gain an especially smooth, dimensionally accurate surface that reduces friction and enables precise fits. Individual markings — for example by (laser) engraving — increase traceability and safety in use.

Finishing

With targeted heat treatments such as hardening, quenching and tempering or nitrocarburizing, we increase hardness and strength, improve wear resistance or enhance corrosion protection. This makes it possible to reliably implement specific component solutions even for the most demanding application areas.

Our specialty: CNC turned parts from mbo Osswald

Our specialty is the production of CNC turned parts exactly in accordance with customer-specific drawings and technical requirements. The offering ranges from simple bar and shaped turned parts to extremely complex functional components with long machining paths, multiple features and individual assembly details. Special solutions or adaptations to specific installation situations are also implemented by us quickly, flexibly and cost-effectively — all based on decades of experience and a continuous technological edge.

Comprehensive service for custom CNC turned parts

At mbo Osswald, we support you from technical advice and a careful analysis of your requirements, through precise manufacturing using state-of-the-art CNC technology, to professional final inspection and flexible logistics. On request, we handle assembly, packaging, special labeling and inventory stocking – so you can rely on maximum supply security, planning reliability and top quality at the optimal time.