Documentation

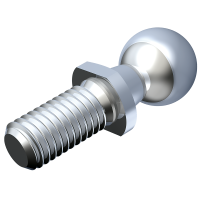

CAD / CAM

Labelling of parts

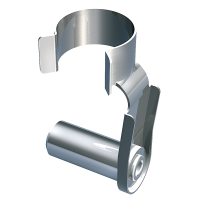

Surface

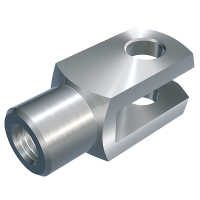

Assembly

Packaging

Cleaning of parts

CAD 3D models

70 employees

1 pieces

8000 m² Warehouse area

19547 packages

Sustainability

3 shifts

365 days

14605 products