The production of custom sleeve nuts at mbo Osswald

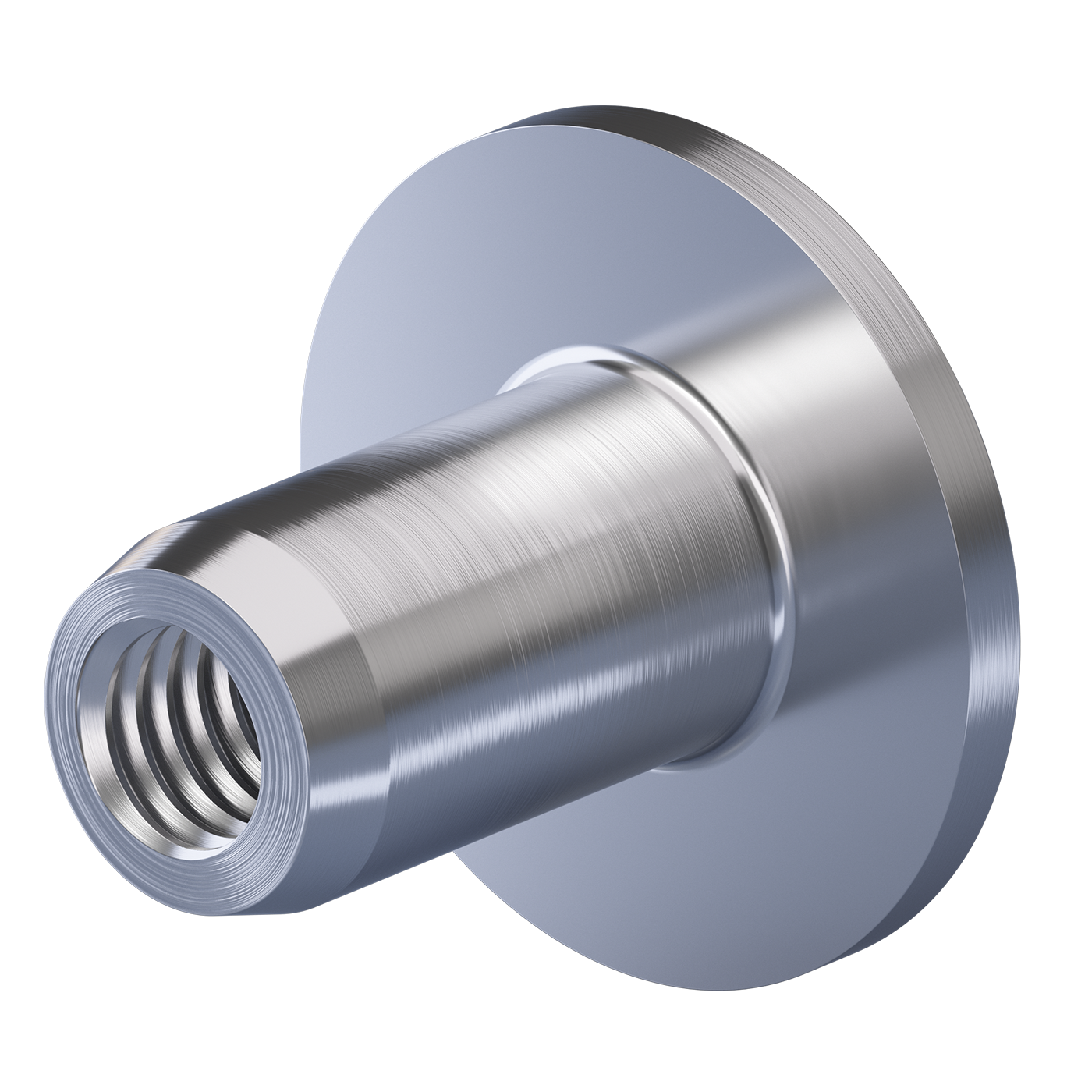

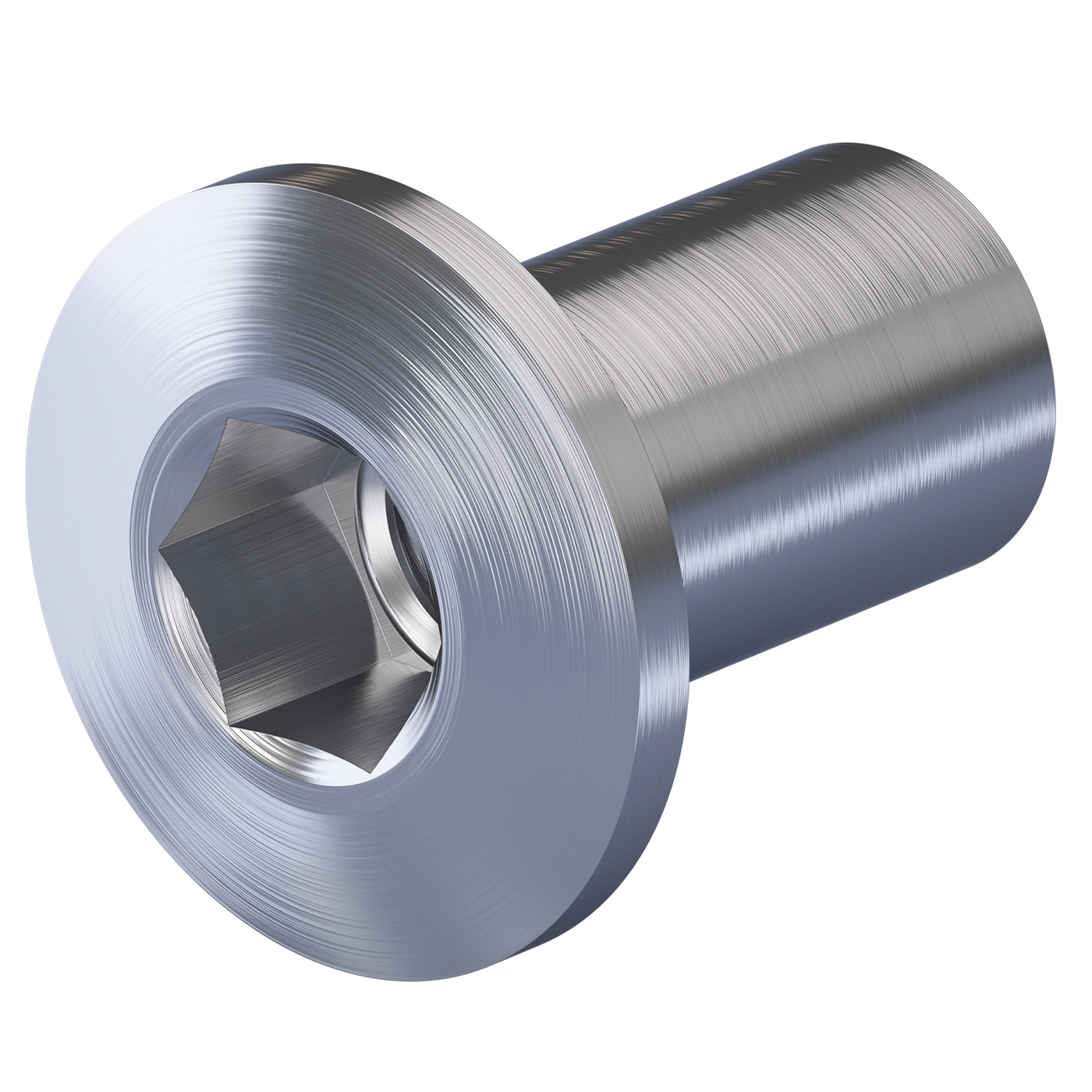

Sleeve nuts are innovative fasteners that combine the precision of high-quality spacer technology with the functionality of conventional nut elements in a single component. As multifunctional connection points they not only provide exact spacing and uniform load distribution, but also enable especially stable, space-saving assembly in demanding technical constructions. The special feature of these components lies in the fusion of sleeve and nut: the integrated nut function further reinforces the connection and facilitates installation across a wide range of thread types and the most complex requirements.

This technical unit of spacer sleeve and fastening nut delivers real added value through greater flexibility, optimized use of space and increased load capacity in mechanical assemblies. Especially in applications where conventional fasteners fall short due to installation space, load profiles or material properties, sleeve nuts manufactured to drawing convince with a tailored fit.

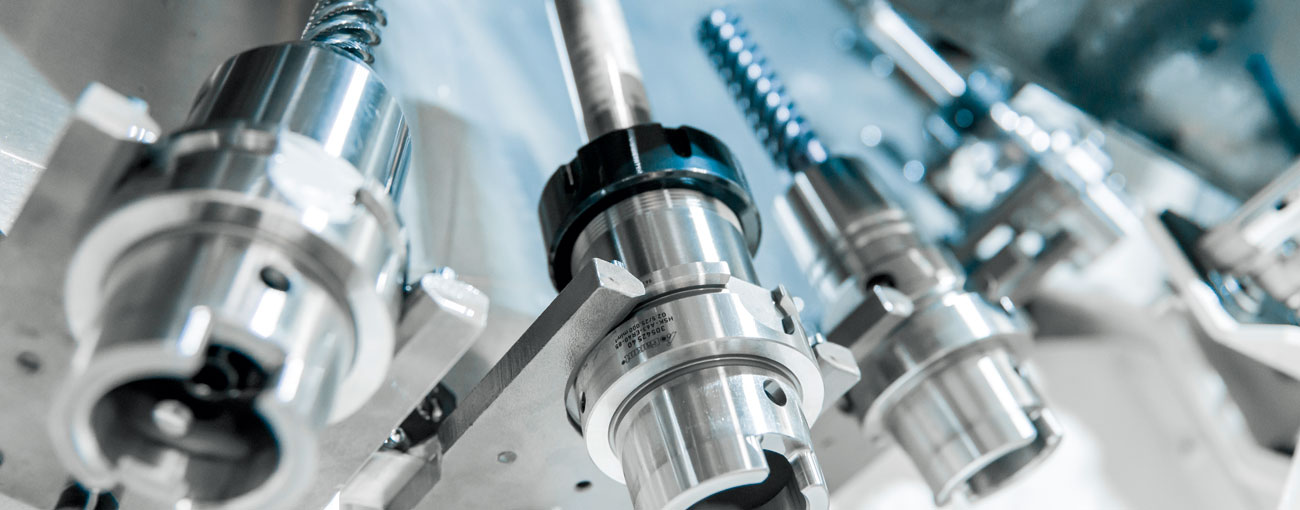

At mbo Osswald we manufacture sleeve nuts exactly according to your drawings, samples or technical specifications - customized in terms of material, dimensions and surface finish. State-of-the-art production technologies, combined with our many years of experience in precision turning and milling parts production, ensure an optimal implementation for any batch size: from single items, prototypes or small series to demanding large-scale production. Our comprehensive service - from planning through manufacturing and assembly to packaging, labeling, logistics and warehousing - ensures that you always receive a well-conceived, durable and technically perfect component for your requirements.

Applications of turned sleeve nuts

The range of possible applications for custom-made sleeve nuts is broad. Their versatility and the principle of functional integration open up practical solutions across a wide range of industries for connection tasks where precision, stability and ease of maintenance are paramount.

Mechanical engineering

In mechanical and plant engineering, sleeve nuts ensure precise assembly positions between machine components, acting as spacer and fastening elements that permanently compensate for high mechanical loads and vibrations. Especially in gearboxes, control units, or demanding assemblies, they secure stable, releasable connections with an exactly defined spacing.

Vehicle construction

In automotive, railway and shipbuilding, turned sleeve nuts play an important role in fastening axles, bushings, booms and thin-sheet metal constructions. They are used wherever confined installation spaces, varying loads and rapid maintenance cycles call for a combination of a spacer and a nut, e.g. when fastening suspension components, steering parts or exhaust systems.

Electronics

In electrical and electronic systems, sleeve nuts secure the assembly-friendly positioning of printed circuit boards, spacer modules and enclosure elements. They provide optimal force transmission and ensure reliable insulation, uniform spacing and rapid assembly of electrical components in space-saving applications.

Furniture industry

For modular or demountable furniture, sleeve nuts offer precise fastening solutions that combine high stability with flexible disassembly capability. Especially in assembly systems for shelves, support frames or system partitions, they ensure defined spacing between components, uniform load-bearing capacity and high assembly efficiency.

Energy generation

In wind and solar power plants, custom-made sleeve nuts help connect load-bearing structural elements with precision and safety. They ensure exact spacing in support structures and rotors and thus enable the reliable absorption and transmission of mechanical loads, even when substantial installation and maintenance work is required in the field.

Construction and building technology

Sleeve nuts secure concealed, flush screw connections in construction and building services. They join components via threaded rods, allow adjustable spacer assemblies and compensate for tolerances. Typical applications include façades, railings, anchor points and building-services trays. Wider bearing surfaces protect finishes; when made of stainless steel they provide corrosion resistance and simplify installation.

Machining areas and materials in the production of sleeve nuts

Our manufacturing expertise covers all machining areas for sleeve nuts: depending on the order we produce diameters from 4 mm to 65 mm and lengths from 5 mm to 350 mm, for prototypes as well as medium and large series. The selection of the appropriate material is made individually according to the application specification and the load profile.

Available materials include undercut steel for standard industrial use, corrosion-resistant stainless steels in A2 and A4 quality for corrosive or hygiene-critical environments, and special or high-performance steels when particular strength, chemical resistance or extreme temperature resistance is required. This ensures that each sleeve nut is optimally tailored to its intended application in terms of service life, load capacity and handling.

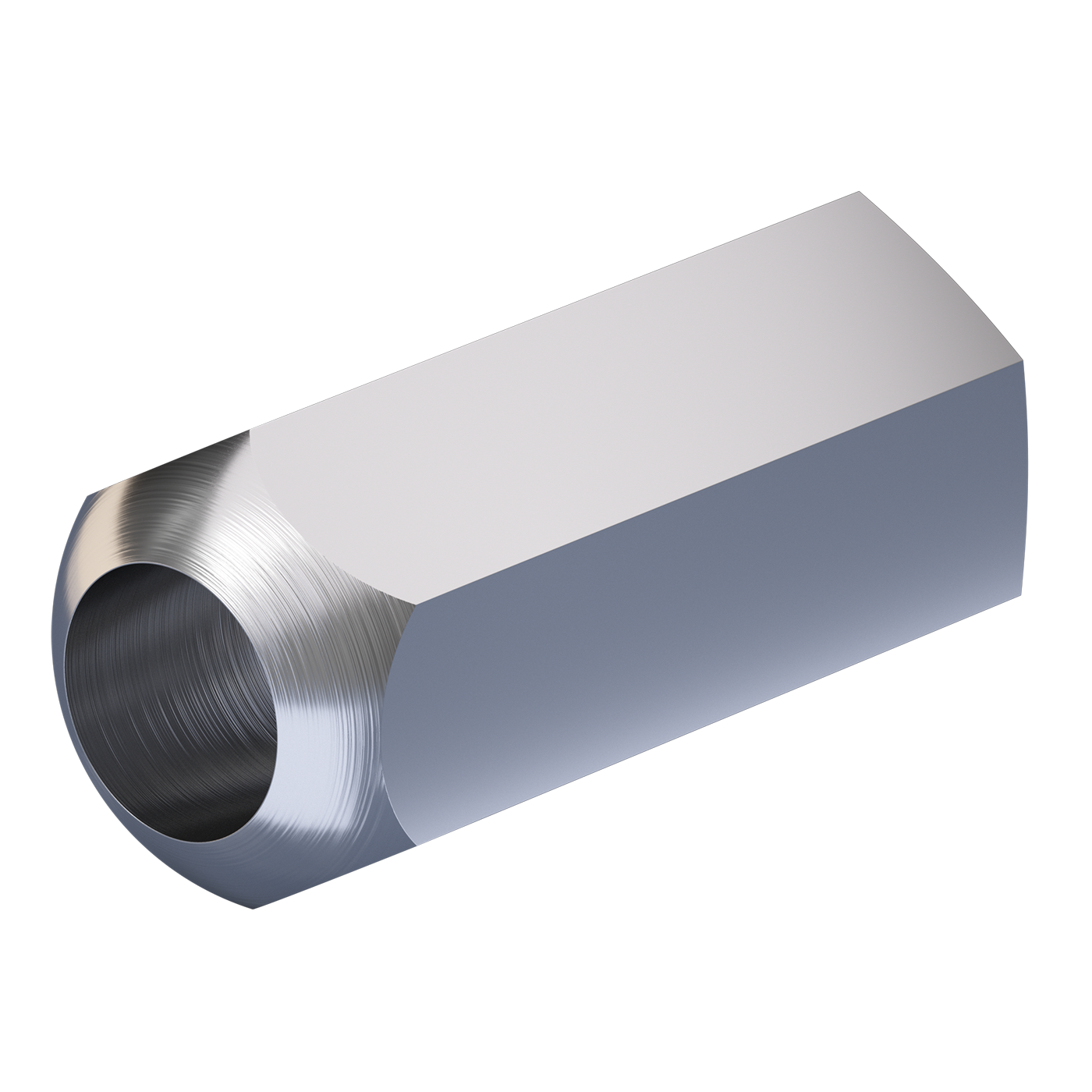

Various shapes and lengths for any quantities

The range of possible shapes and dimensions for sleeve nuts is extensive. We manufacture classic cylindrical shapes, stepped nuts, variants with polygonal sections, collar, drive recesses for screwdrivers or special head geometries. Machine and customer drawings are translated precisely into the desired geometry and, thanks to our flexible production control, single-piece lots, pilot batches and reliable series deliveries are all implemented smoothly.

Combined variants, for example with different internal/external thread types, complex milled contours or specific fit tolerances, can also be manufactured to exact dimensions. Our machinery provides the necessary flexibility to respond efficiently to changing project requirements, short-term modifications or pilot series during the development process.

The most common materials: steels and alloys according to load profile

The material portfolio for sleeve nuts includes a wide selection of robust, high-performance materials. For standard applications, undercut steels are suitable, as they combine high machinability and cost-efficiency with good dimensional stability.

In environments with moisture, chemicals, or in food processing, we primarily rely on stainless steels of grades A2/A4. For industries with very specific requirements, special alloys and specialty steels - such as heat-resistant, seawater-resistant, or high-strength variants - are also available. Through the coordinated choice of materials, we deliver sleeve nuts that provide lasting protection, highest strength, and maximum service life.

Sleeve nuts – Extensive machining options

Thanks to modern turning and milling technology, a wide range of machining options is available for producing custom sleeve nuts: cross holes, grooves, milling operations, polygonal machining, spanner surfaces, internal hex, special contours, as well as metric or inch internal threads in standard or fine, right- or left-hand versions.

These manufacturing possibilities are complemented by the production of special shapes (e.g. sealing grooves, collar reinforcements, milled or combined head forms), the integration of specialized functional areas and by individual markings using laser engraving or stamping. Each machining step is precisely tailored to your requirements and the interfaces of your design, ensuring a technically and economically perfect connection.

Various surface finishes for your sleeve nuts

The choice of the appropriate surface treatment plays a decisive role in the durability, appearance and functionality of your sleeve nuts. Different processes are combined depending on the area of application, assembly requirements or industry-specific standards:

Coating

Electroplating processes such as galvanizing (zinc-plating), passivation, phosphating or bluing provide targeted protection against corrosion, wear or attack by aggressive media. Technically or visually specifically modified special coatings are also possible to provide additional functionality or to achieve a distinctive design.

Treatment

For sensitive applications, grease-free, oil-film–coated, or temporarily protected surface treatments are available. Each method is selected to ensure that assembly, storage and operation proceed smoothly and safely.

Mechanical machining

Precise grinding, custom engravings and markings are used to stabilise dimensions, enable quick identification and ensure complete traceability. The surface always remains first-class, both visually and technically.

Finishing

Targeted heat treatments (such as hardening, tempering and nitrocarburizing) purposefully increase the wear resistance, surface hardness and corrosion resistance of the sleeve nut – supplementing the chosen base materials and tailored individually to sustained loading and special applications.

The specialty: sleeve nuts from mbo Osswald

Our specialty is manufacturing sleeve nuts precisely according to drawings, individual dimensional specifications and specific load profiles. The spectrum ranges from simple guide sleeves with an integrated nut function, through compact spacer connections for electronics or furniture constructions, to highly complex, function-integrated special nuts for drive and safety systems.

In addition to classic standard designs and standard sizes, we also produce bespoke special variants, for example for applications with increased hygiene requirements, as special forms for vibration-loaded installations, or for highly precise, detachable threaded connections. Our machinery and equipment, together with our experts, guarantee reliability, short response times and consistently high quality in every production batch.

Comprehensive service for sleeve nuts according to drawing

From the initial idea to integration into your operations, you benefit from our comprehensive service approach. We accompany you from the technical feasibility analysis, through the optimization of manufacturing drawings, material selection and process planning, to explicit quality control at every stage of production.

In addition, we offer flexible, project-tailored logistics: we are happy to take on complete warehousing, assembly preparation, special packaging and individual labeling of your sleeve nuts. Framework orders, short-term quantity fluctuations and urgent requirements are no problem for us thanks to our digitized production planning and efficient communication structures, as are industry-specific additional requirements. With mbo Osswald you rely on process-oriented partner expertise from a single source.