Fast-track this part (max. 400 units) through our production facility. Shorten the delivery time by 1-2 working days. We are currently exclusively testing this delivery service for Germany.

incl. VAT

plus shipping costs

To cancel your filter settings again, click on the "Clear" button below the table.

You can display product details, including the eShop function and 3D model , by clicking in the row corresponding to the required article.

1. Product description

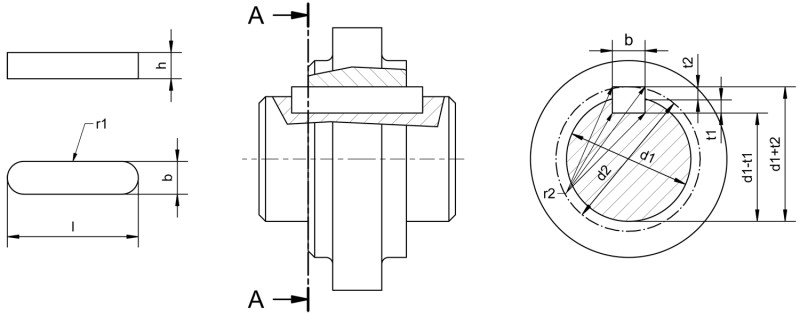

Parallel keys DIN 6885 form A (round-ended, high-sized version) are widely used in mechanical engineering and plant construction where a reliable, non-rotating connection between a shaft and a hub is required. These machine elements enable the transmission of torque and prevent relative rotation between the connected components. Due to their precise manufacturing and high form, they ensure maximum contact area between shaft and hub, resulting in efficient power transmission.

2. Product details

Size: A 2x2x6 - A 100x50x400

Material group: Steel, stainless steel

Surface: bright

Width b: 2 - 100

Height h: 2 - 50

Length l: 6 - 400

3. Application Areas & Compatibility

Mechanical engineering: Used in gearboxes, clutches, pumps, and engines, where parallel keys help to safely transmit mechanical power. In almost all areas of general mechanical engineering, parallel keys are central to the assembly of rotating components.

Automation technology: They are also used in automation to precisely control the movement of mechanical parts in automated production lines and robots.

Drive technology and motor engineering: In electric motors, generators, and other drive systems, parallel keys are used to anchor rotors and other rotating parts.

Automotive engineering: In the various sectors of vehicle engineering, parallel keys are used to connect drive shafts, wheel hubs, steering columns, and other transmitting parts.

Wind power: In wind turbines, parallel keys secure the connection between the hub and the drive shaft as well as other critical connection points that are exposed to high loads.

Shipbuilding and marine: In shipbuilding, they are used to fix propeller shafts, pumps, and other elements of the drive system.

Conveyor technology: In conveyor technology, parallel keys are used to fasten rollers, drums, and pulleys to efficiently move materials.

Agricultural engineering: In agriculture and forestry, parallel keys are used in tractors, harvesters, and other agricultural machines for power transmission.

Energy technology: In both conventional and renewable energy plants, they are used to secure turbines, generators, and other key components.

Compatibility: The compatibility of parallel keys DIN 6885 form A ensures they can be used with a wide range of shaft and hub configurations. They are available in various sizes, allowing flexible adaptation to specific shaft diameters and keyway widths. Selecting the right size and specification is crucial to ensure optimal fit and thus reliable performance of machine elements. It is also important to ensure compliance with other relevant standards and application-specific requirements to guarantee full compatibility and performance.

4. Advantages and Benefits

Reliable power transmission: Thanks to their precise manufacturing and specific shape, parallel keys fit seamlessly into the corresponding keyways of the shaft and hub. This ensures optimal power transmission and prevents twisting or slipping under load. Form A, with its specific profile, provides even better load distribution and transfer.

Easy installation and removal: One of the main features of parallel keys is their simplicity in installation and removal. No special tools or procedures are required, which saves time and costs, especially during maintenance and repair work. This accessibility also makes it easy to inspect and replace parallel keys when worn, without damaging the shaft or hub.

High adaptability: Parallel keys DIN 6885 form A are available in a wide variety of sizes and materials, allowing their use in different mechanical configurations and operating environments. From light-duty applications to high-performance uses in industry - there is a suitable parallel key for almost every requirement.

Durability: Manufactured from high-quality key steel according to DIN 6880 or stainless steel, parallel keys offer high strength and corrosion resistance. This contributes to a long service life, even in demanding environments such as outdoors or in applications exposed to chemicals.

Cost efficiency: In addition to their high performance and reliability, parallel keys are a cost-effective solution for power transmission. Their simple installation and the possibility of reuse further help reduce overall costs.

Overall, parallel keys DIN 6885 form A not only provide a reliable solution for connecting machine elements, but also improve the efficiency and cost-effectiveness of the design and maintenance of machines and systems, making them a preferred choice for engineers and designers worldwide.

5. Assembly and Installation

Tools and preparation:

- Make sure you have all the necessary tools at hand, including appropriate protective equipment.

- Check the dimensions of the shaft, hub, and parallel key to ensure they fit together.

- Thoroughly clean the keyway of the shaft and the hub to remove dirt and corrosion. This ensures a good fit and optimal performance.

Inserting the parallel key:

- Carefully place the parallel key into the slot on the shaft. The parallel key should fit into the slot without being too loose or too tight. Light tapping with a plastic hammer may be required to fully insert it, but be careful not to damage the parallel key.

- Ensure that the parallel key is flush with the shaft or slightly below the surface to allow the hub to slide on smoothly.

Mounting the hub:

- Slide the hub over the end of the shaft so that the slot of the hub is aligned with the parallel key.

- It may be necessary to use slight pressure or gentle hammer blows to bring the hub into the correct position on the shaft. Again, it is important to avoid damage from excessive force.

Final inspection and alignment:

- After assembly, check the alignment of the shaft and hub to ensure the connection is correct and the parallel key serves its function.

- Perform a visual inspection to make sure that no part of the parallel key is protruding or that there are other signs of faulty installation.

Maintenance:

- After assembly, it is advisable to regularly check the parallel key connection for wear or loosening, especially in applications exposed to high loads or vibrations. A careful assembly process ensures that the parallel key serves its intended purpose efficiently and ensures a long service life of the connection.

6. Safety instructions & Standards

Within the design and assembly of machine elements, such as parallel keys DIN 6885 form A, adherence to safety instructions and standards is crucial to prevent accidents and ensure a high level of reliability and performance of mechanical connections.

DIN 6885: This standard defines the shapes, dimensions, and tolerances of parallel keys used for connections between rotating elements and shafts. Compliance with this standard ensures that the parallel keys are universally applicable and interchangeable, which improves compatibility and performance in assembly.

Frequently Asked Questions (FAQ)

What are parallel keys DIN 6885 form A?

What is the difference between parallel keys DIN 6885 form A (round-ended, high-sized version) and the parallel keys DIN 6885 form B (straight-ended, high-sized version)?

The main difference lies in the design of their end faces:

- Round-ended (form A): Parallel keys DIN 6885 form A have rounded ends on both sides. This rounding facilitates installation, as it fits into the corresponding curves of the keyway openings in the shaft and hub. The round end form is suitable for applications where easy assembly and disassembly are required, and where the parallel key connection does not need to be released frequently.

- Straight-ended (form B): In contrast, parallel keys DIN 6885 form B have straight end faces. These straight ends fit into keyways with a correspondingly right-angled opening. Parallel keys with straight ends can enable better power transmission in certain applications, especially when high torques are involved or when a more precise positioning of the parallel key is needed.

Both forms are available in a high-sized version, which indicates their relative thickness and thus their ability to transmit power. The choice between these two forms depends mainly on the specific application, the requirements for assembly and disassembly, and the configuration of the shaft-hub connection.